On-Site Insight: Rigorous Occupational Health Monitoring Underway at RISEWELL

- marketing2176330

- Jul 1, 2025

- 1 min read

Updated: Aug 20, 2025

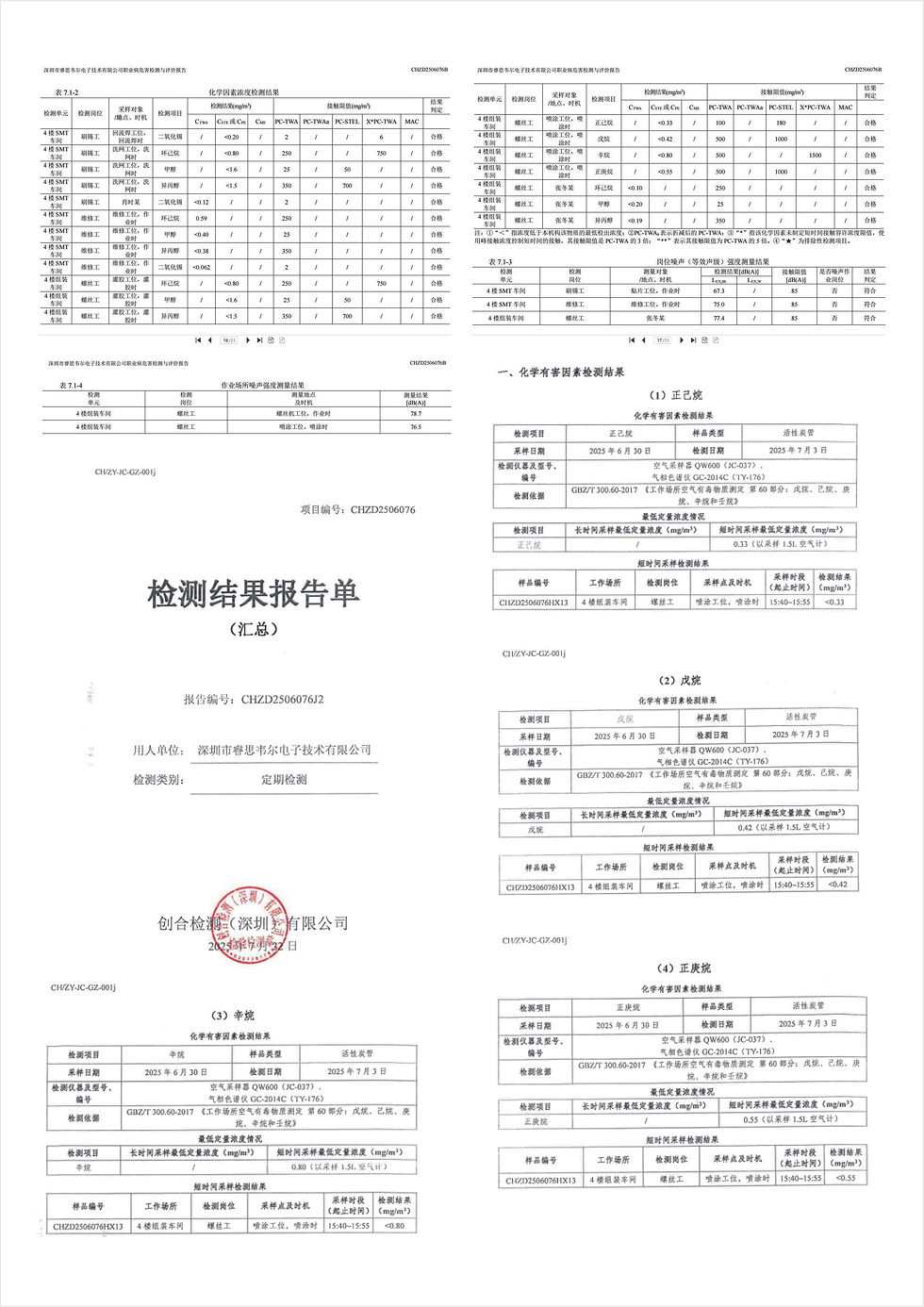

RISEWELL, [June 2025] — Certified industrial hygienists are conducting comprehensive workplace exposure assessments across our production facilities this week. This annual monitoring, performed by accredited third-party specialists, exemplifies our commitment to ISO 45001 standards and employee well-being before product excellence.

Behind the Scenes: Precision in Action

① Scientific Setup

Technicians configure real-time aerosol monitors near reflow ovens - instruments calibrated to NIST traceable standards.

② Real-Time Exposure Mapping

Air sampling during hand soldering operations, capturing tin oxide levels at the breathing zone with personal lapel samplers.

③ Material Hazard Analysis

Sealed collection of solder paste, isopropanol, conformal coatings, and potting compounds for laboratory VOC analysis.

Why Process Matters

✓ Third-Party Credibility follow OSHA 29 CFR 1910.1200 protocols

✓ Worker Engagement:

10+ employees participating in exposure profiling

On-site training on chemical handling best practices

Workshop | Process | Hazards Monitored | Samples |

4F SMT | Reflow Soldering | Tin Oxide | 3 |

| Stencil Cleaning | Iso-propanol, Cyclohexane | 6 |

| Component Mounting | Noise | 3 |

4F Module Asm. | Potting | 9 Solvents* | 9 |

| Conformal Coating | 21 VOCs** | 21 |

| Screw Fastening | Noise | 3 |

Occupational Monitoring Results Timeline

Full laboratory analysis of the 32 occupational exposure samples will be available by July 20, 2025. All findings will be published in our Q3 Sustainability Report with corrective action plans.

Comments